- Home

- CNC Turn Milling

CNC Turn Milling

CNC Turn Milling

CNC Turn Milling Overview:

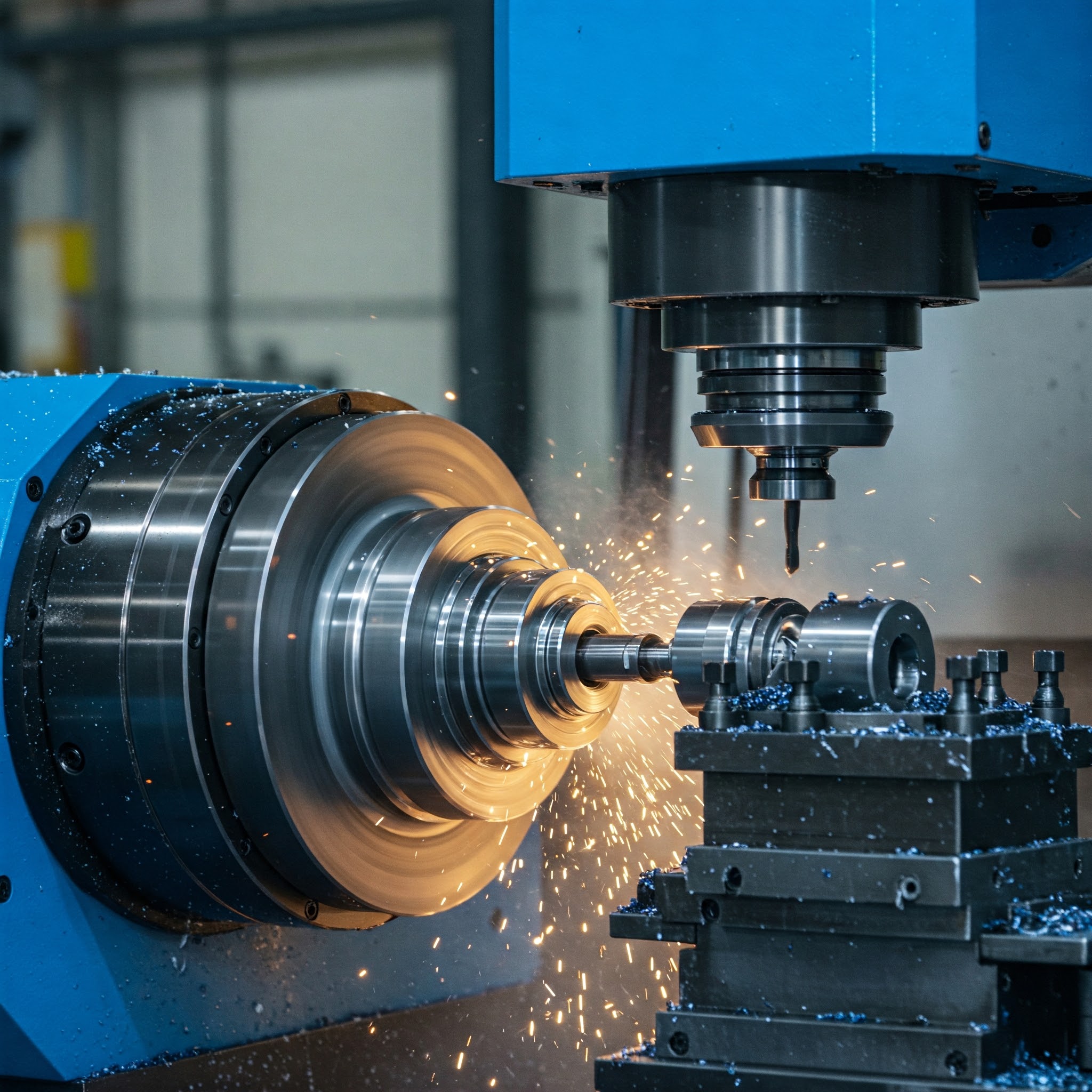

CNC turn milling is a hybrid machining process that combines turning and milling operations in a single setup. It allows for the creation of complex parts with both cylindrical and prismatic features, improving efficiency and precision while reducing production time.

CNC turn milling integrates both turning (rotating workpiece) and milling (rotating cutting tool) operations, enabling more complex geometries in a single setup.

It reduces setup time, enhances precision, and allows for intricate designs with multiple features in one machining process.

A wide range of metals (aluminum, titanium, stainless steel) and plastics can be processed efficiently.

Aerospace, automotive, medical, and industrial sectors use it for complex components requiring high precision.